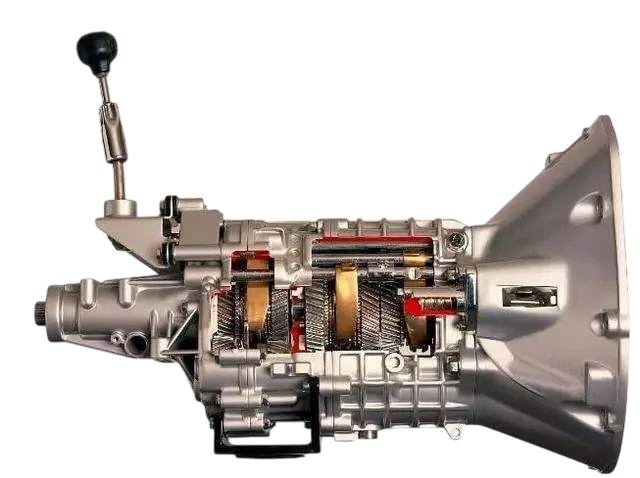

Manual Transmission (MT)

In a manual transmission, the driver needs to manually operate the gearshift lever to adjust the gear combination inside the transmission, thereby changing the gear ratio to achieve speed changes. Although automatic transmissions are becoming more and more popular nowadays, the manual transmission still holds an important position in the racing world and in the hearts of consumers who pursue a driving experience. Some high-performance sports cars still favor it.

Advantages: The structure is relatively simple, which makes its production cost and maintenance cost low, and it has strong reliability. It has good fuel economy and a high power transmission efficiency, which can more effectively transmit the engine’s power to the wheels. The gearshift response is rapid. The driver can precisely control the vehicle’s power output by operating the clutch and gearshift lever, providing more interactivity and driving pleasure for the driver. Especially in cornering or situations where the vehicle speed needs to be adjusted frequently, the timeliness and accuracy of manual gear shifting can bring a great driving experience.

Disadvantages: The operation is relatively complex. For novice drivers, it takes a certain amount of time and practice to master the coordination of the clutch and accurate gear shifting. There will inevitably be a sense of jerking during the gearshift process, especially in congested traffic conditions. Frequent gearshift operations may make the driver feel fatigued.

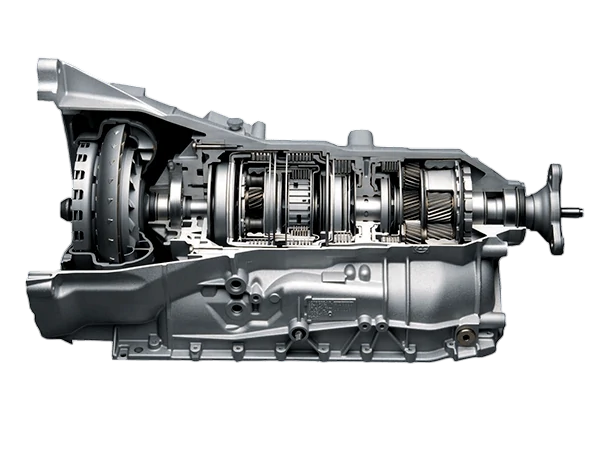

Hydraulic Automatic Transmission (AT)

The AT transmission is mainly composed of a torque converter, a planetary gear set, and a hydraulic control system. It transmits power through a liquid medium and combines different gear combinations to achieve speed changes and torque variations. The torque converter is its core component, which includes components such as the pump impeller, the turbine, and the stator. It is not only responsible for torque transmission but also acts like a clutch. In the Chinese market, when it comes to automatic transmissions, it usually refers to the AT transmission.

Advantages: The operation is simple and intuitive. The driver only needs to gently step on the accelerator to achieve a smooth gearshift experience without manual operation, which greatly simplifies the driving process and provides a more smooth and comfortable driving experience. It can automatically adjust the speed and torque according to the road conditions, making the vehicle more relaxed and free during driving. The technology is mature, and it has high reliability, which can effectively prevent the engine from overspeeding or overloading.

Disadvantages: The structure is relatively complex and the weight is relatively large, resulting in a higher cost for cars equipped with AT transmissions. The maintenance difficulty and cost are also higher. Compared with the manual transmission, there is a certain energy loss in the power transmission process, which may lead to higher fuel consumption, and the acceleration performance may also be slightly inferior.

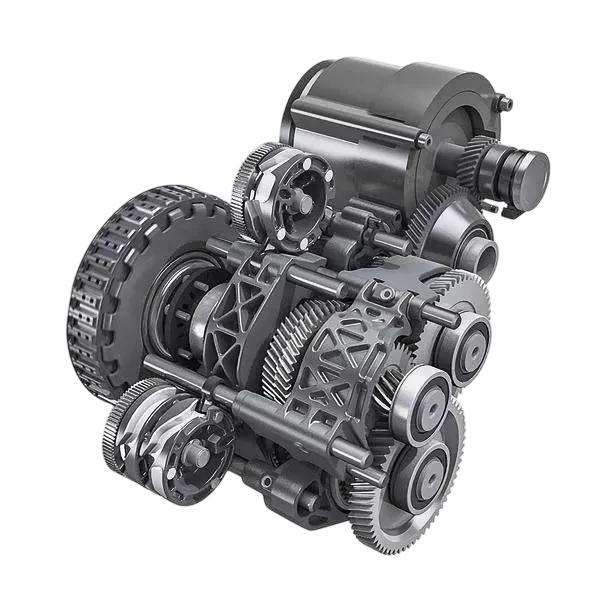

Continuously Variable Transmission (CVT)

The core components of the CVT are a pair of pulleys and a metal belt. Each pulley is composed of two movable discs. By adjusting the distance between the discs, the diameter of the contact between the metal belt and the pulley can be changed, thus achieving continuous and smooth speed changes. This avoids the jerking feeling during gear shifting of traditional gear transmissions and ensures continuous power transmission.

Advantages: It provides an extremely smooth driving experience, and the gear shifting is flexible and free. Due to its efficient energy transmission characteristics, its fuel efficiency is better than most automatic transmissions, second only to the manual transmission. Its lower emission level also makes it more environmentally friendly. The structure is relatively simple.

Disadvantages: The manufacturing cost is relatively high. If it is not used properly or maintained poorly, the risk of failure may increase. The maximum torque that the steel transmission belt can withstand is limited. In high-load situations, the power performance may not be as expected. And it is difficult to repair, and the cost is high. It is not suitable for extreme off-road driving.

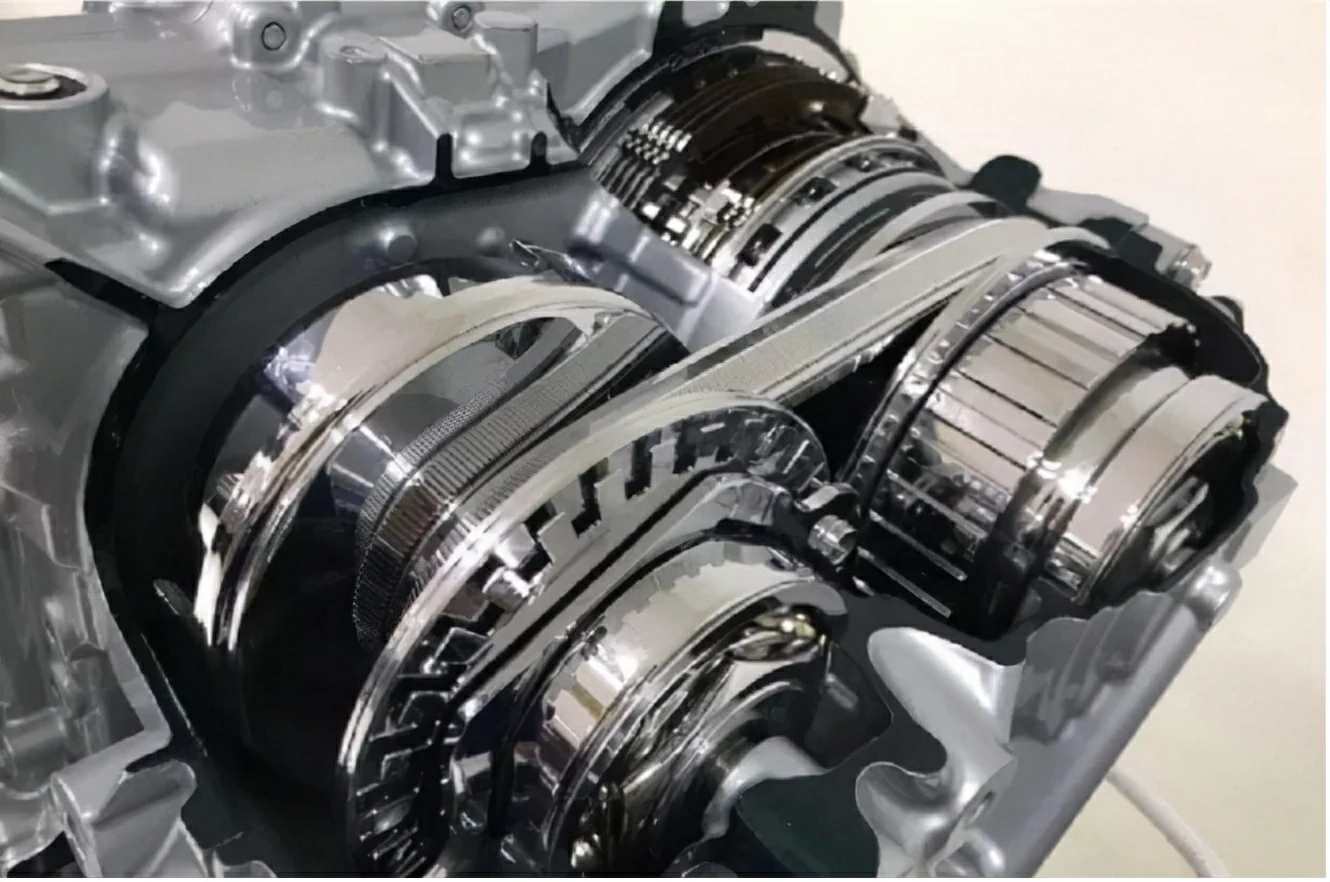

Dual Clutch Transmission (DCT)

The DCT dual-clutch transmission uses two sets of clutches to work together. One set is responsible for controlling the odd-numbered gear gears, and the other set is responsible for the even-numbered gear gears. The purpose is to overcome the problem of power interruption during the gearshift process of traditional manual transmissions. It prepares the other set of clutches in advance to immediately take over the current work and quickly change to the required gear to maintain the continuity of power transmission.

Advantages: It provides excellent acceleration performance and high transmission efficiency, ensuring the smoothness and response speed of power transmission. The gearshift speed is fast, the bearing capacity is high, and it has good fuel economy.

Disadvantages: The manufacturing process is complex and the cost is high, which is reflected in the higher purchase price and relatively high maintenance cost. There is a serious sense of jerking at low speeds.