I. Working Principle

The working principle of a manual transmission is based on the fundamental principle of gear transmission. By meshing gears with different numbers of teeth, it achieves changes in rotational speed and torque. Simply put, the power of the engine is transmitted to the input shaft of the transmission through the clutch, and then through gear shifting operations, different gear combinations are meshed to transmit the power to the output shaft, ultimately driving the wheels to rotate.

To understand this process more clearly, let’s take a common five-speed manual transmission as an example. When the vehicle is in neutral, there is no direct power connection between the input shaft and the output shaft, and the power of the engine cannot be transmitted to the wheels. When the driver depresses the clutch pedal, the power transmission between the engine and the transmission is cut off, and at this time, different gears can be selected through the gear shift lever. For example, when shifting into first gear, the first gear set meshes, and the power is transmitted from the input shaft to the first gear driven gear through the first gear driving gear. Since the number of teeth of the first gear driven gear is more than that of the first gear driving gear, according to the principle of gear transmission, the rotational speed of the output shaft decreases, but the torque increases, thus providing sufficient power for the vehicle to start.

When the vehicle needs to accelerate, the driver depresses the clutch pedal again and shifts to a higher gear, such as the second gear. In the second gear, the second gear set meshes. Since the number of teeth of the second gear driven gear is relatively fewer than that of the first gear driven gear, the rotational speed of the output shaft increases accordingly, and the torque decreases, allowing the vehicle to travel at a higher speed. Similarly, by shifting to different gears, the vehicle can keep the engine operating within a more appropriate rotational speed range under different driving conditions, thus achieving the best power output and fuel economy.

II. Structural Composition

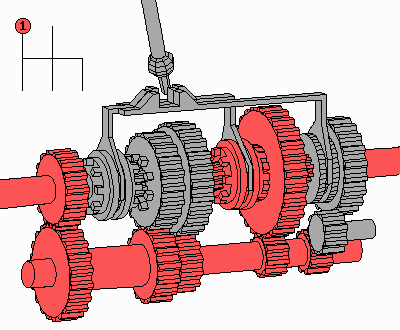

The manual transmission is mainly composed of two major parts: the speed change transmission mechanism and the speed change operation mechanism.

(I) Speed Change Transmission Mechanism

The speed change transmission mechanism is the core part of the manual transmission, and its main function is to change the magnitude and direction of the torque. It is usually composed of components such as the input shaft, output shaft, intermediate shaft (some transmissions do not have one), gears of each gear position, synchronizers, and bearings.

- Input Shaft: It is connected to the clutch, receives the power transmitted from the engine, and transfers it to other components inside the transmission. A constantly meshing gear is usually installed on the input shaft, and this gear always meshes with the constantly meshing gear on the intermediate shaft.

- Output Shaft: It is responsible for transmitting the power after speed change to the differential, and then driving the wheels. Driven gears of each gear position are installed on the output shaft, and these gears are connected or disengaged from the output shaft through synchronizers to achieve the shifting of different gears.

- Intermediate Shaft: In some manual transmissions, the intermediate shaft plays the role of transmitting power and changing the rotational speed and torque. Multiple gears with different numbers of teeth are installed on the intermediate shaft, and these gears mesh with the gears on the input shaft and the output shaft to achieve different gear ratios. For example, in a three-axis manual transmission, the power is transmitted from the input shaft to the intermediate shaft, and then from the intermediate shaft to the output shaft. Through the combination of different gears, a variety of gear ratio changes are achieved.

- Gears: The gears in the manual transmission are the key components for achieving speed change. Gears with different numbers of teeth mesh with each other, and by changing the gear ratio, the adjustment of rotational speed and torque is realized. Generally speaking, the gear ratio of low gears is large, which is used to provide a large torque and is suitable for working conditions such as vehicle starting and climbing. The gear ratio of high gears is small, which is used to achieve a higher vehicle speed and is suitable for the vehicle to travel at high speed on a flat road.

- Synchronizer: The synchronizer is an indispensable component in modern manual transmissions. Its main function is to make the gears to be meshed reach the synchronous rotational speed during the gear shifting process, reduce the impact and noise during gear shifting, and achieve smooth gear shifting. The synchronizer is usually composed of components such as the synchronizer ring, slider, and spline hub. During gear shifting, the synchronizer ring makes the rotational speeds of the gears to be meshed tend to be the same through friction, and then the slider pushes the synchronizer ring to make the gears mesh smoothly. For example, when shifting from the first gear to the second gear, the synchronizer will make the rotational speed of the second gear driven gear synchronous with the rotational speed of the output shaft, making the gear shifting process smoother.

(II) Speed Change Operation Mechanism

The function of the speed change operation mechanism is to achieve gear shifting operations, enabling the driver to conveniently and accurately select the required gear. It is mainly composed of components such as the gear shift lever, shift fork, shift fork shaft, and some locking devices.

- Gear Shift Lever: The driver selects different gears by operating the gear shift lever. The gear shift lever is usually located in the cab for the driver’s convenience. There are various operation methods for the gear shift lever, and the common one is the “H” type gear shifting mode. The driver can shift between different gears by moving the gear shift lever forward, backward, left, and right.

- Shift Fork: The shift fork is connected to the gear shift lever. When the driver operates the gear shift lever, the shift fork will, under the drive of the shift fork shaft, push the synchronizer or the sliding gear to achieve gear shifting. The design and manufacturing accuracy of the shift fork have an important impact on the smoothness and accuracy of gear shifting.

- Shift Fork Shaft: The shift fork shaft is used to install the shift fork and, through the linkage with the gear shift lever, realizes the movement of the shift fork. A locking device is usually set on the shift fork shaft to prevent the occurrence of automatic gear disengagement or the engagement of multiple gears simultaneously during the gear shifting process.

- Locking Devices: The locking devices in the manual transmission mainly include the self-locking device, interlock device, and reverse gear lock device. The function of the self-locking device is to prevent automatic gear disengagement. It locks the position of the shift fork shaft by setting a groove and a steel ball on the shift fork shaft, so that the steel ball is embedded in the groove under the action of the spring. The function of the interlock device is to prevent the engagement of two gears at the same time. It prevents the movement of other shift fork shafts when one shift fork shaft moves by setting an interlock pin between the shift fork shafts. The function of the reverse gear lock device is to prevent accidentally shifting into reverse gear during forward driving. It usually sets additional resistance or a locking mechanism on the gear shift lever, so that the driver needs additional operations when shifting into reverse gear to avoid misoperations.

III. Types of Manual Transmissions

According to different classification criteria, manual transmissions can be divided into various types. Common classification methods include classification by the number of working shafts and classification by the change mode of the gear ratio.

(I) Classification by the Number of Working Shafts

- Two-Shaft Manual Transmission: The two-shaft manual transmission is mainly applied to front-engine front-wheel drive (FF) vehicles. It has the characteristics of simple and compact structure, with only two shafts, namely the input shaft and the output shaft, and the two shafts are parallel to each other. In a two-shaft manual transmission, the gears on the input shaft directly mesh with the gears on the output shaft to achieve power transmission and speed change. Since there is no intermediate shaft, the power transmission path is relatively short, and the transmission efficiency is relatively high. In addition, the two-shaft manual transmission usually integrates the differential inside the transmission, and together with the drive axle, it is called a manual transaxle, further simplifying the structure and reducing the production cost. For example, models such as the Volkswagen Golf use a two-shaft manual transmission.

- Three-Shaft Manual Transmission: The three-shaft manual transmission is often used in front-engine rear-wheel drive (FR) vehicles. In addition to the input shaft and the output shaft, it also has an intermediate shaft. The power is transmitted from the input shaft to the intermediate shaft, and then from the intermediate shaft to the output shaft. Through the combination of different gears on the three shafts, a variety of gear ratio changes are achieved. The advantage of the three-shaft manual transmission is that it can provide more gear selection options to adapt to different driving conditions. At the same time, due to the existence of the intermediate shaft, the arrangement of the input shaft and the output shaft is relatively more flexible, facilitating the overall layout of the vehicle. For example, some medium and large-sized sedans and some commercial vehicles use a three-shaft manual transmission.

(II) Classification by the Change Mode of the Gear Ratio

- Step-Type Manual Transmission: The step-type manual transmission is the most common type of manual transmission. It has several fixed gear ratios, and the switching of these gear ratios is achieved through the meshing of different gears. Generally speaking, the number of gears of a step-type manual transmission is 4 to 6, and the common ones are 5-speed and 6-speed manual transmissions. Different gears are suitable for different driving speeds and road conditions, and the driver can select the appropriate gear according to the actual situation. For example, when driving in urban areas, lower gears are usually used to ensure the vehicle’s power and flexibility; when driving on the highway, higher gears can be shifted to improve fuel economy and driving stability.

- Continuously Variable Manual Transmission (Theoretically Exists but Seldom Used in Practice): The gear ratio of a continuously variable manual transmission can change continuously within a certain range, rather than having only a few fixed gears like a step-type manual transmission. Theoretically, this type of transmission can keep the engine always in the best working state, thereby improving fuel economy and power performance. However, in practical applications, due to the relatively high technical difficulty and cost, the continuously variable manual transmission is not common. Currently, continuously variable transmission technology is mainly applied in the field of automatic transmissions, such as the common CVT (Continuously Variable Transmission) continuously variable transmission.

IV. Analysis of Advantages and Disadvantages

(I) Advantages

- Lower Cost: The structure of the manual transmission is relatively simple, with fewer components, and the manufacturing process is relatively not complicated. Therefore, its manufacturing cost is relatively low. This makes vehicles equipped with manual transmissions usually more price-competitive than those equipped with automatic transmissions. For consumers with a limited budget, a manual transmission vehicle is a more cost-effective choice. In addition, due to its simple structure, the manual transmission is also relatively inexpensive in terms of later maintenance and repair. The maintenance difficulty is relatively low, and the prices of the required maintenance parts are also relatively low.

- High Transmission Efficiency: The power transmission of the manual transmission is direct. During the gear shifting process, the power loss is relatively small, and almost all the power of the engine can be transmitted to the wheels. In contrast, due to the existence of components such as the torque converter in the automatic transmission, there will be certain energy losses during the power transmission process. Therefore, the manual transmission can enable the vehicle to obtain better power performance under the same conditions. For example, it has more advantages in acceleration and climbing, and can give full play to the performance of the engine.

- Good Fuel Economy: Due to the high transmission efficiency of the manual transmission and the small power loss during the transmission process, vehicles equipped with manual transmissions usually consume less fuel than automatic transmission vehicles under the same driving conditions. This is a very important advantage for owners who often drive long distances or are more sensitive to fuel costs. Especially on roads other than urban areas, such as highways, the fuel-saving advantage of the manual transmission is more obvious. Through reasonable gear shifting operations, the driver can keep the engine running within a more economical rotational speed range, thereby reducing fuel consumption.

- High Driving Fun: The process of manual gear shifting requires the driver to operate actively. The driver can flexibly select the appropriate gear according to their own driving intentions and road conditions, and better participate in the driving process, experiencing the fun of controlling the vehicle. For those who like driving and pursue driving skills, a manual transmission vehicle can provide a more direct and intimate driving experience, allowing the driver to feel the realm of “the unity of man and vehicle”. For example, in cornering or situations where the vehicle speed needs to be adjusted frequently, the timeliness and accuracy of manual gear shifting can bring great driving fun, making the driving process more challenging and interesting.

- Strong Reliability: The manual transmission adopts a pure mechanical structure, without complex electronic control systems and hydraulic systems. Its technology is mature and durable. Compared with the automatic transmission, the failure rate of the manual transmission is relatively low. Especially in some harsh usage environments, such as high temperature and high humidity, the reliability advantage of the manual transmission is more obvious. Even if a failure occurs, due to its relatively simple structure, it is easier for maintenance personnel to diagnose and repair the problem.

(II) Disadvantages

- Complex Operation: Driving a vehicle with a manual transmission requires the driver to master the coordination of the clutch and the gear shift lever operation. For beginners, the operation difficulty is relatively high, and it takes a certain amount of time to learn and adapt. During the starting and gear shifting processes, the driver needs to accurately control the engagement and disengagement timing of the clutch and cooperate with the operation of the gear shift lever. Otherwise, situations such as stalling and jerking are likely to occur. In addition, in urban congestion conditions, the frequent gear shifting operations will increase the driver’s fatigue, making driving no longer easy.

- High Requirement for Driving Skills: The driver needs to accurately select the appropriate gear according to factors such as the vehicle speed and the engine rotational speed to ensure the smooth running of the vehicle and the normal operation of the engine. If the gear shifting timing is not appropriate, it will not only affect the vehicle’s power performance and fuel economy but may also cause damage to the engine and the transmission. For example, if a low gear is accidentally shifted into when driving at high speed, it may cause the engine rotational speed to be too high, increasing the wear of the engine. If a high gear is shifted into when driving at a low speed, it may make the vehicle’s power insufficient, and even cause situations such as shaking and stalling. Therefore, vehicles with manual transmissions have relatively high requirements for the driver’s driving skills and experience.

- Poor Comfort: During the gear shifting process, due to the interruption and reconnection of power, a certain amount of jerking will inevitably occur. Especially when the driver’s operation is not proficient, the jerking will be more obvious, which will affect the driving comfort. In contrast, the gear shifting process of the automatic transmission is automatically completed by the control system, and the gear shifting is smooth, which can provide a more comfortable driving and riding experience. In addition, during long-distance driving, vehicles with manual transmissions require the driver to frequently operate the clutch and the gear shift lever, which is likely to make the driver feel fatigued, further reducing the driving comfort.

V. Application Scenarios and Development Trends

(I) Application Scenarios

Although the market share of automatic transmissions is gradually increasing, the manual transmission still has irreplaceable advantages in some specific application scenarios.

- Driving Enthusiasts: For those driving enthusiasts who pursue driving fun and enjoy the control process, the manual transmission is their first choice. Manual transmission vehicles allow them to better control the vehicle and experience the passion and challenge of driving. For example, in motorsports, the manual transmission is still widely used. Race car drivers can more accurately control the vehicle’s power output through manual gear shifting to achieve the best race results.

- Specific Vehicle Models: The manual transmission also has important applications in some specific vehicle models. For example, in some small trucks and pickups, since they are mainly used for cargo transportation and have high requirements for the vehicle’s economy and reliability, the low cost, high reliability, and good fuel economy of the manual transmission make it an ideal choice for these vehicle models. In addition, some hardcore off-road vehicles are also equipped with manual transmissions to meet the precise control requirements of off-road enthusiasts for the vehicle’s power and handling in complex road conditions.

(II) Development Trends

With the continuous development of automotive technology, the market share of manual transmissions is gradually being squeezed by new types of transmissions such as automatic transmissions, dual-clutch transmissions (DCT), and continuously variable transmissions (CVT). However, the manual transmission will not disappear quickly. It is still constantly evolving and improving. On the one hand, automobile manufacturers are striving to improve the gear shifting comfort and operation convenience of manual transmissions. By optimizing the design of synchronizers and improving the gear shifting mechanism, they are reducing the operation difficulty of manual transmissions and enhancing the driving experience. On the other hand, in order to meet the increasingly strict environmental protection and energy-saving requirements, manual transmissions are also developing in the direction of improving transmission efficiency and reducing fuel consumption. For example, by using more advanced gear materials and manufacturing processes, the friction loss between gears is reduced, and the transmission efficiency of manual transmissions is further improved. In addition, with the rise of new energy vehicles, the manual transmission has also found new application scenarios in some hybrid vehicles. Through cooperation with electric motors, it can achieve more efficient power output and energy utilization.

As an important part of the automotive transmission system, although the manual transmission faces competition from new types of transmissions such as automatic transmissions, it still occupies a place in the automotive market due to its own unique advantages. Whether for consumers who pursue driving fun or in some specific vehicle models and application scenarios, the manual transmission has irreplaceable value. With the continuous progress of technology, the manual transmission is also constantly innovating and developing to adapt to market demands and changes.