I. What is a Transmission?

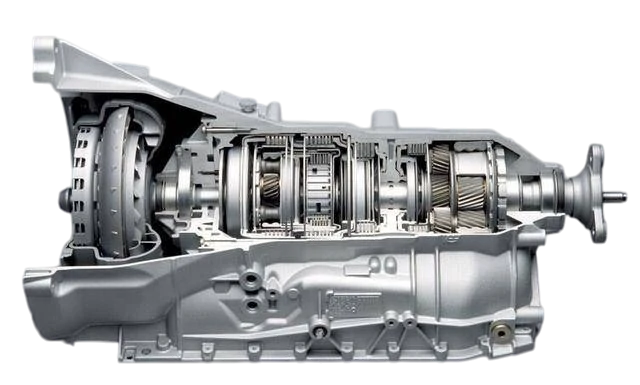

The transmission is a key component of the automobile’s transmission system. Its main responsibility is to coordinate the engine’s rotational speed with the actual driving speed of the wheels, achieving different gear ratios to meet the needs of the automobile under various driving conditions. Structurally, it mainly consists of two major parts: the input and the output. Inside, it contains components such as shafts, bearings, gears, synchronizers, shift forks, self-locking and interlocking devices, and the housing. Simply put, it is like a precise mechanical hub that transmits the power generated by the engine to the wheels in the most appropriate way.

II. The Functions of a Transmission

- Changing the Gear Ratio: During the driving process of an automobile, the road conditions and driving requirements vary greatly. For example, when starting, climbing a slope, or driving at a low speed, a large driving force is required. At this time, the transmission will adopt a lower gear ratio, allowing the wheels to obtain a greater torque. When driving at a high speed, in order to improve fuel economy and vehicle speed, the transmission will switch to a higher gear ratio, reducing the torque of the wheels and increasing the rotational speed. In this way, the transmission expands the range of changes in the torque and rotational speed of the driving wheels, enabling the engine to operate under more favorable working conditions.

- Realizing the Reverse Function: With the engine rotating in the same direction, the transmission can, through a specific gear combination, enable the automobile to move in reverse, meeting the reverse driving needs in daily driving.

- Interrupting the Power Transmission: By using the neutral gear, the transmission can interrupt the power transmission between the engine and the transmission system. This allows the engine to start easily and idle smoothly. At the same time, it also facilitates the driver to perform gear shifting operations or other operations related to power output.

III. The Working Principle of a Transmission

The working principles of different types of transmissions are different. Below, we will introduce the common manual transmission and automatic transmission as examples.

(I) Manual Transmission

The manual transmission is mainly composed of gears and shafts. The driver changes the meshing positions of different gears by manually operating the gear shift lever, thus generating different gear ratios to achieve the purpose of changing speed and torque. Each gear corresponds to a different gear ratio, just like the meshing of a small gear and a large gear, which can produce different rotational speeds. When driving at a low speed, a low gear ratio (such as gears 1 – 3) is used. At this time, the rotational speed of the main shaft is lower than that of the engine. According to the formula P = FV (power = force × speed), a greater driving force can be obtained. When driving at a high speed, switch to a high gear ratio (such as gear 4 and above), and the rotational speed of the main shaft is higher than that of the engine, reducing the traction force to obtain a higher speed. This type of transmission has a relatively simple structure, lower cost, good stability and reliability, but the operation is relatively complex and requires a high level of driving skills from the driver.

(II) Automatic Transmission

The automatic transmission (AT) is generally composed of a torque converter, planetary gears, and a hydraulic control system. The power of the engine is first transmitted to the torque converter, which is a three-element mechanical mechanism. The power (torque) uses the oil as the medium and is transmitted from the pump impeller to the turbine through the stator. When there is a rotational speed difference between the turbine and the pump impeller, the oil will be guided by the internal structure of the torque converter to more fully transmit the energy transmitted by the pump impeller to the turbine, increasing the torque of the turbine. This is the torque multiplication function of the torque converter. The greater the rotational speed difference between the pump impeller and the turbine, the more significant the torque multiplication effect.

The power enters the planetary gear shifting mechanism from the torque converter through the main shaft. There are multiple sets of planetary gear pairs working simultaneously here. Each set of planetary gears is composed of a sun gear, planet gears, and an outer ring gear. By fixing one of the components and rotating another component, the third component can rotate at a different rotational speed or in a different direction. Different combinations of multiple planetary gear pairs can obtain multiple different gear ratios and directions. In addition, there is a series of multi-plate clutches in the planetary gear shifting mechanism. The disengagement or engagement of these clutches enables different combinations of planetary gear pairs, thus generating multiple forward gears (D gear) and reverse gears (R gear). The control of the automatic transmission is completed by the hydraulic control valve plate. It can continuously sense the changes in the engine and vehicle speed, load, and road conditions, and control the corresponding clutches through the hydraulic system to achieve automatic gear shifting. The gear shifting operation of the automatic transmission is more convenient, and the driving comfort is high, especially suitable for driving in urban congested road conditions.

IV. Common Types of Transmissions

In addition to the above-mentioned manual transmission and automatic transmission, there are also the following common types:

- Continuously Variable Transmission (CVT): It transmits power through a steel belt or steel chain. Two cone pulleys press the steel belt through hydraulic control, and the power is transmitted using static friction. Its biggest feature is that the speed change process is continuous and smooth, without an obvious gear shifting feeling, and the driving experience is very smooth. At the same time, it can effectively reduce fuel consumption. However, its acceleration response is relatively slow, and the torque it can withstand is limited.

- Dual Clutch Transmission (DCT): Developed based on the manual transmission, it combines the advantages of both manual and automatic transmissions. It achieves fast gear shifting through two sets of clutches and is divided into dry dual clutch and wet dual clutch. This type of transmission has a fast gear shifting speed, high transmission efficiency, and low fuel consumption. But the dry dual clutch has the problem of transmission overheating, and there may be a jerking feeling when driving at a low speed. Moreover, the wear of the dual clutch is relatively fast, and its quality stability is not as good as that of the automatic transmission.

- Automated Manual Transmission (AMT): It is an improvement on the manual transmission by adding an electronic control system to achieve automatic gear shifting operation. It has a relatively low cost and high transmission efficiency, but there may be a certain jerking feeling during the gear shifting process, and the driving comfort is slightly inferior.

V. Maintenance of the Transmission

The normal operation of the transmission is crucial to the performance and service life of the automobile. Therefore, regular maintenance is required:

- Check the Oil Level: Regularly check whether the oil level of the automatic transmission is normal. The method of checking the automatic transmission oil is different from that of checking the engine oil. The oil needs to be preheated to about 50°C, and then move the gear shift lever to each gear and keep it there for 2 seconds before placing it in the parking gear. At this time, the normal oil level on the dipstick should be between the highest and lowest lines. If it is insufficient, add the same quality of oil in a timely manner.

- Replace the Transmission Oil: Most manufacturers recommend that the replacement cycle of the automatic transmission oil is generally two years or 40,000 – 60,000 kilometers. During the use of the transmission oil, the working temperature is relatively high, and it is easy to produce oil stains and impurities, which will affect the system oil pressure and power transmission. Therefore, replace the transmission oil in a timely manner. Currently, a better method of changing the oil is dynamic oil change. Use a special transmission cleaning device. During the operation of the transmission, fully circulate and discharge the old oil, and then add new transmission oil, so that the oil change rate can be as high as more than 90%, ensuring a good oil change effect.

- Regular Inspection and Maintenance: Regularly conduct a comprehensive inspection of the transmission, including checking the wear conditions of components such as gears, synchronizers, and clutches, and promptly discover and solve potential problems. At the same time, pay attention to keeping the transmission clean and avoid impurities from entering the inside of the transmission, which may affect its normal operation.