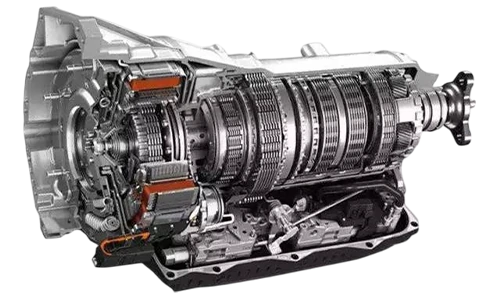

In the complex structure of an automobile, the transmission, as a core component of the power transmission system, plays a crucial role in efficiently and accurately transmitting the power of the engine to the wheels. Its performance directly affects the vehicle’s power output, fuel economy, and driving experience. The key factors determining the performance of a transmission are precisely the complex and sophisticated manufacturing processes and the carefully selected materials behind it.

I. Manufacturing Processes of Transmissions

(I) Machining of Gear and Shaft Parts

- Forging Blanking: Hot die forging is a common process for forging blanks of gear and shaft parts. By applying pressure to the metal blank at high temperatures, it undergoes plastic deformation to obtain a blank close to the final shape of the part. This effectively improves the density and strength of the material. In recent years, cross-wedge rolling technology has been widely promoted in shaft machining, especially suitable for blanking of complex stepped shafts. This technology has the advantages of high precision, small machining allowance, and high production efficiency. For example, when manufacturing the input and output shafts of an automobile transmission, cross-wedge rolling technology can precisely control the external dimensions of the shaft, reducing the workload of subsequent machining processes.

- Normalizing Treatment: After forging blanking, a normalizing process is required. Its purpose is to enable the metal material to obtain an appropriate hardness and, at the same time, prepare the microstructure for the subsequent final heat treatment, effectively reducing deformation during the heat treatment process. Normalizing treatment can homogenize the internal structure of the material and improve its machinability, providing good conditions for subsequent machining.

- Precision Turning: To meet high-precision requirements, precision turning of gear blanks and shaft parts is usually carried out on numerically controlled lathes. A numerically controlled lathe can precisely control the movement trajectory of the cutting tool according to the pre-set program, performing turning operations on the parts to ensure the machining dimensional accuracy and surface finish. During the machining process, precise machining of various surfaces such as the outer circle, inner hole, and threads of the parts can be achieved.

- Tooth Profile Machining: Tooth profile machining is a key link in gear manufacturing. Common machining methods include gear shaping, gear hobbing, and gear shaving. Gear shaping is mainly used for machining internal gears and multiple gear trains; gear hobbing is suitable for machining external gears and can efficiently machine gears of various modules and numbers of teeth; gear shaving is a finishing method for the gear tooth surface, which can further improve the accuracy and surface finish of the tooth surface, reducing noise and wear during gear operation.

- Heat Treatment: Heat treatment is an important process for improving the performance of gear and shaft parts, generally including processes such as quenching and tempering. Through heat treatment, parts can obtain good comprehensive mechanical properties, such as increased hardness, strength, and wear resistance, while maintaining a certain degree of toughness. For example, after carburizing and quenching treatment, the tooth surface hardness of the gear is greatly increased, while the core still maintains good toughness, making it less likely to suffer from tooth surface wear, fatigue spalling, and other failure modes when subjected to high-load operation.

- Grinding and Meshing Correction: Parts may experience certain deformation after heat treatment. Grinding is carried out to eliminate these deformations and ensure the final dimensional accuracy and surface quality of the parts. Grinding is usually performed on high-precision grinding machines, grinding the key parts of the parts. Meshing correction is the paired lapping of gears to make the tooth surfaces of the meshing gears contact better, further improving the smoothness and load-bearing capacity of gear transmission.

(II) Machining of Housing Parts

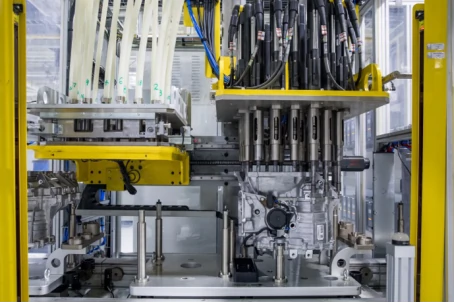

- Assembly Process: The assembly of the transmission is a complex and delicate process that requires strict operation in accordance with the assembly process requirements. Before assembly, all parts need to undergo strict quality inspection to ensure that they meet the design requirements. During the assembly process, attention should be paid to parameters such as the installation sequence of each part, the assembly clearance, and the tightening torque. For example, when assembling the gear and the shaft, it is necessary to ensure their coaxiality and tooth side clearance; when assembling the clutch, it is necessary to ensure that its clamping force and separation stroke meet the standards. At the same time, special assembly tools and equipment should be used to ensure the consistency and stability of the assembly quality.

- Detection Technology: In order to ensure the performance and quality of the transmission, multiple detections are required during the manufacturing process. In addition to the above-mentioned detection of the dimensional accuracy, shape accuracy, and surface quality of individual parts, the overall performance of the assembled transmission also needs to be detected. Common detection items include:

- Engine Idle Speed Detection: When the water temperature is normal and the transmission is in the “N” gear, detect whether the engine idle speed is within the specified range. Unstable engine idle speed may be due to some faults in the transmission components, which affect the power transmission between the engine and the transmission.

- Throttle Cable Detection: Check whether the throttle opening can be accurately reflected on the throttle inside the automatic transmission to ensure the accuracy and sensitivity of throttle control.

- Gear Selection Mechanism Detection: Observe whether the transmission rod is deformed or interfered with, and whether the joints are properly fixed. Shift the gear selector lever into each gear, feel whether the handle is flexible and in the correct position, and at the same time, check whether the neutral start switch, overdrive control switch, forced downshift switch, etc. are working properly, and whether the oil level of the automatic transmission meets the standard.

- Gear Detection: Check whether all gears, including manual gear selection, manual gear shifting, and forward gear shifting, are working well, and whether the shifting process is smooth without any jamming.

- Stall Detection: Detect the engine speed when the vehicle speed is zero, aiming to check the overall performance of the automatic transmission and the engine. Before the detection, ensure that the engine and transmission are in normal condition and take safety precautions. During the detection, engage the parking brake, step on the brake pedal, shift the gear shift lever to the “D” or “R” position, quickly press the accelerator pedal to the bottom, and record the engine speed. Note that the detection time should be controlled, and let the engine idle for a while to cool down after the detection is completed.

- Electronic Control System Component Detection: Check electronic components such as the vehicle speed sensor, shift solenoid valve, oil pressure control solenoid valve, control switch, and oil temperature sensor to see if there are any short circuits, open circuits, poor contacts, damage, or failures. The electronic control system is an important part of modern automatic transmissions, and the reliability of its performance directly affects the shifting logic and control accuracy of the transmission.

- Hydraulic Test: Turn off the engine, put the transmission in the “P” gear, and connect the oil pressure test pipe joint, hose, and pressure gauge. Start the engine, and after the transmission reaches the normal oil temperature, test and record the oil pressure under various working conditions. By comparing with the standard values, judge the working condition of the hydraulic system. The hydraulic system is responsible for controlling the shifting actuators and clutches inside the transmission. Abnormal oil pressure may lead to problems such as shifting delays, jolts, or even inability to shift.

- Road Test: Before the test, check the vehicle’s appearance and safety items to ensure that the engine and transmission oil meet the requirements. Road test items include starting condition detection, acceleration drive performance test, constant speed drive system performance test, high-load high-speed drive transmission system performance test, deceleration and coasting performance detection, automatic shifting detection, engine braking performance test, forced downshift function detection, torque converter lock-up function detection, etc. Through the road test, the performance of the transmission during actual driving can be comprehensively evaluated, and potential problems can be discovered and adjusted and optimized in a timely manner.

II. Commonly Used Materials for Transmissions

(I) Gear Materials

- Alloy Steel: Due to its high strength, high wear resistance, and good heat treatment performance, alloy steel is widely used in the manufacture of transmission gears. Especially in the transmissions of high-performance cars and commercial vehicles, alloy steel gears can withstand high loads and high speeds, ensuring the reliability and durability of the gears during long-term use. For example, 20CrMnTi is one of the commonly used alloy steel materials for automotive transmission gears in China. After carburizing and quenching treatment, the tooth surface hardness can reach HRC58 – 62, and the core hardness is HRC30 – 45, with good comprehensive mechanical properties.

- Carbon Steel: For the transmission gears of some family cars with lower loads and speeds, carbon steel is also a commonly used material. Carbon steel has the advantages of low cost and good machinability, and can meet the use requirements under general driving conditions. For example, 45 steel can also obtain good strength and wear resistance after appropriate heat treatment and is widely used in the manufacture of transmission gears for economy cars.

(II) Shaft Materials

- Carbon Steel: Generally, economic carbon steel is often selected as the basic material for the shaft parts of the transmission, such as 45 steel. Through a reasonable heat treatment process, such as quenching and tempering treatment, the shaft can obtain good comprehensive mechanical properties to meet the strength and stiffness requirements under most working conditions.

- Alloy Steel: When the gear and the shaft are integrally designed, or the shaft needs to bear a large load, alloy steel materials will be selected. Alloy steel has higher strength and toughness and can adapt to harsher working environments, ensuring that the shaft will not undergo deformation or fracture and other failure forms during long-term use.

(III) Housing Materials

- Cast Iron: Cast iron has high strength, good wear resistance, and casting performance, and the cost is relatively low. Therefore, it is widely used in the manufacture of transmission housings for heavy commercial vehicles. For example, gray cast iron HT200 has high compressive strength, can withstand the large internal pressure of the transmission, and its good casting performance makes it easy to manufacture complex housing structures.

- Aluminum Alloy: Aluminum alloy materials have the characteristics of low density and light weight, and are increasingly used in the manufacture of transmission housings for high-performance cars and light vehicles. Using an aluminum alloy housing can effectively reduce the vehicle’s own weight, improve fuel economy and handling performance. At the same time, aluminum alloy also has good corrosion resistance and can adapt to different usage environments. Although the cost of aluminum alloy is relatively high, its performance advantages make it play an important role in modern automotive manufacturing.

(IV) Bearing Materials

- Special Alloy Steel: In the transmissions of high-performance cars and commercial vehicles, since the bearings need to work under high-speed, high-temperature, and high-load conditions, special alloy steel is often used for manufacturing. Special alloy steel has higher hardness, wear resistance, and high-temperature resistance, which can ensure the reliability and service life of the bearings under harsh working conditions.

- Ordinary Bearing Steel: For the transmissions of general family cars, ordinary bearing steel can meet their usage requirements. Ordinary bearing steel has good strength and wear resistance, and the cost is relatively low. On the premise of ensuring certain performance, it can effectively control the manufacturing cost of the transmission.

(V) Other Materials

- Synchronizer Materials: The synchronizer is an important component for achieving smooth shifting. Commonly used materials include copper alloys and alloy steels. Copper alloys have good friction performance and wear resistance, can quickly achieve synchronization during the shifting process, and reduce shifting impact; alloy steel synchronizers have higher strength and durability and are suitable for high-load working environments.

- Seal Materials: The seals of the transmission are mainly used to prevent oil leakage. Commonly used materials include rubber and silicone rubber. Rubber seals have good elasticity and sealing performance, low cost, and are widely used; silicone rubber seals have better high-temperature resistance and aging resistance and are suitable for some occasions with high sealing requirements.

- Lubricants: Transmission lubricants (i.e., transmission oil) play a vital role in ensuring the normal operation of the transmission. It can not only lubricate various moving parts, reduce friction and wear, but also play the roles of heat dissipation, cleaning, and power transmission. Commonly used transmission oils include mineral oils, semi-synthetic oils, and fully synthetic oils. Fully synthetic oils have better high-temperature performance, low-temperature fluidity, and oxidation resistance and can meet the requirements of high-performance transmissions and use under harsh working conditions; mineral oils and semi-synthetic oils are suitable for general family car transmissions, and the cost is relatively low.

The manufacturing process and material selection of the transmission are a closely related and mutually influencing systematic project. Advanced manufacturing processes can fully utilize the performance advantages of materials, while high-quality materials provide a basic guarantee for the realization of manufacturing processes. Only by continuously innovating and optimizing in manufacturing processes and material selection can we produce transmissions with excellent performance and high reliability, meet the continuous development needs of the automotive industry, and bring consumers a better driving experience.